Potters® Performance Materials business works closely with customers to provide value-added performance additives that uniquely improve customer formulations by lowering cost and increasing performance.

Our microspheres serve as functional additives in industrial applications such as weight-reducing fillers in plastics, polymers, and automotive body putties, as extenders in adhesives and paints/coating formulations, sensitizers in industrial explosives, electromagnetic shielding for electronic parts, and abrasive applications for cleaning and peening metal surfaces.

Remember SPHERES:

- Safe – Amorphous, no crystalline silica

- Particle – tight particle size doesn’t affect finish

- Hard – 6 on the Mohs scale, makes coatings tough

- Engineered – Designed particle size distribution, lot-to-lot consistency

- Round – True spheres, “ball bearing” effect

- Environmental – Glass is GRAS and inert

- Smooth – Low surface area per unit volume, not a resin “hog”

Q-CEL®

Low-Density Performance Additive

- Resin Extension in polymers translates to cost savings

- Increased solids, reduced VOC’s

- Emulsion Explosives Sensitizer

- Improved mold/flow in thermoset applications

- Improved thermal cycling properties in coatings/composite from insulation factor

- Higher solid loading without viscosity increase

- Acrylic Patching/filling compounds

- Markets/Applications include construction, automotive, composites, coatings, oil well cements

- Fewer defects: excellent mold flow, uniform dispersion

- Reduced compound density and viscosity

- Increased acoustic and thermal insulation

- Reduced cost and better handling in flexible compounds

- More uniform, closed-cell structure in syntactic compounds

- Cost reduction from sandpaper and labor savings for putties

SPHERICEL®

Weight-Reducing, High-Strength Additive

- Reduce weight in engineered plastics (grades available in 0.25 g/cc to 1.1 g/cc)

- Increase durability (grades available up to 10,000 psi crush strength)

- Increase abrasion and burnish resistance

- Reduce VOC content without compromising viscosity and flow

- Improve film integrity without changing finish

- Provides insulation and floatation effect

- Easy to disperse into formulations

LUXSIL®

A Multi-Functional Beauty-Enhancing Additive for Cosmetics

- Provides a pleasant, soft powdery feel to a variety of cosmetic formulas

- Smoothness and flow are enhanced by the ball bearing effect of tiny spheres

- Gives excellent hiding properties with a unique soft focus due to light scattering

- Aids in distribution of other particles, enhancing their performance

- Non-porous/non-absorbent

- Colorless

- Good compressibility

- Particle size – mean diameter 9-13µm

LUXSIL AL Free Product Overview

LUXSIL Cosmetic Product Overview

SPHERIGLASS®

Delivering Technical and Economic Advantages

Technical and economic advantages can result from the inclusion of SPHERIGLASS® solid glass spheres as a performance additive for thermoplastic and thermosetting resin systems. Their multiple benefits include enhanced processing and reduced manufacturing costs.

Glass spheres are smooth, hard, offer excellent chemical resistance and low oil absorption. These and other characteristics enable the spheres to be used in a wide range of applications in the transportation, automotive, chemical, electronic, industrial, and engineering industries, where they can substantially reduce reject rates in production.

- Improve flow properties

- High resin displacement

- Low shrinkage and warpage

- Better molded parts

- Improve surface hardness, toughness and durability

- Improve abrasion/ scratch resistance

- High flexural modulus

- Better stress distribution

- Excellent chemical resistance

Spheriglass Flooring Product Overview

Spheriglass Product Overview

SPACER BEADS FOR ADHESIVES

Specialized glass beads specifically designed for controlling bond line thickness in adhesive bonding

- These beads are manufactured and certified to meet the specification requirements of Raytheon HMS20-1776 and Boeing SCGMS-53004

- Variety of particle sizes to meet specific functional and end-use application requirements

- Utilized in Automotive, Aerospace, Chemical and Electronics applications.

MEDISPHERE®

For Use in Air-Fluidized Support Systems Treating Burns, Grafts and Pressure Sores

- Air-fluidization technology uses microspheres to achieves fluid properties in a completely dry medium

- Microspheres increase density of artificial fluid, for more stable support with less pressure on patient wounds

- Particulate filtering effect reduces airborne contamination while trapping body fluids for removal

TECHNICAL QUALITY GLASS MATERIALS

For Industrial Grinding, Dispersing and Deagglomerating

- Economical, multi-use media for grinding other particulate materials

- Effectively deagglomerates, for improved particle dispersion within resin, solvent or other suspensions

- Chemically-inert media ideal for delaminating minerals from lode-bearing rock

- No ferrous or other residues to contaminate plate-metal surfaces

Driving Green Alternatives

Glass powders (100 mesh to 600 mesh) are widely used in C.A.S.E (coatings, adhesives, sealants and elastomer-polymers) markets as a crystalline silica free recycled functional filler. Other applications include anti-block, ceramics, glazes, and frit.

Glass sands (12 mesh to 100 mesh) are used in stucco, traffic markings, pool filtration, and many other applications where being white and transparent has advantages. The glass sands are also free of crystalline silica.

Leading Glass Powder Characteristics:

- Free of Crystalline Silica

- Inert/Corrosion Resistance

- Abrasion Resistant

- Low Specific Gravity

- 100% Recycled Content

- Uniform Color

- Uniform Particle Size Distribution

- Surface Modifiable

Leading Glass Sand Characteristics:

- Uniform, consistent gradation

- Silica free

- Minimal label remnants

- High Brightness

Product Overview

BALLOTINI® IMPACT BEADS

For Metal Cleaning, Finishing, Peening and Deburring

- Rapid results: clean, finish, peen and deburr in one step

- Results: clean finish without significant metal removal or changing tolerances

- Versatile: create a wide range of reproducible surface finishes

- Economical: can be recycled/reused many times

- Chemically inert: no ferrous or other residues

- Industry leader: over 90 years experience

- Grades: AMS 2431/6D, MIL SPEC PRF 9954D and Commercial sizes available

Cleaning Overview

Peening Overview

Finishing Overview

Sizing Comparison Overview

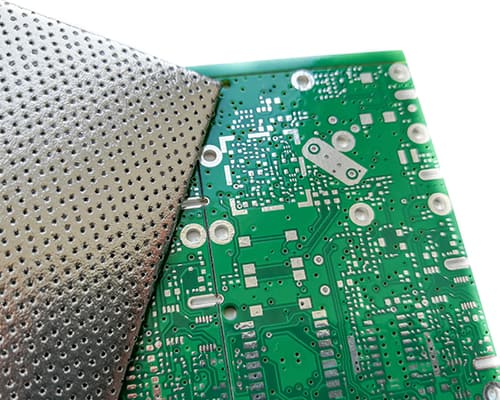

Conductive Particles

The family of Conduct-O-Fil® particles can provide lower cost and lower weight replacements to expensive pure silver and high density nickel powders used in consumer, industrial and military markets. Specific applications include adhesives, lacquers, coatings, lubricants, greases, gaskets and a host of EMI shielding solutions.

Conduct-O-Fil® particles are two component particles consisting of a specially chosen core material that is plated with a precious metal coating. At the center of the technology is the ability to provide highly controlled particles having various shapes, sizes, and distributions with exact and uniform deposition of metal to the particle surface. A wide selection of Silver, Nickel and Gold coated products are commercially available coated on a variety of inner core particles including: Aluminum, Copper, Nickel, Ferrite, Glass and others. Every product is engineered to meet the wide array of demands required by the conductive markets we serve.

Key benefits include:

- High volume capacity with reproducible quality

- High level conductivity

- Size, shape and density selection diversity

- Excellent particle stability

- Oxidation resistance

- Cost savings potential

Conduct-O-Fil® Product Overview

Green Construction Materials

Custom-engineered, high performance, pozzolanic additives for use in cement, mortar, concrete, stucco, faux stone and related products.

Potters Industries is the leading manufacturer of glass powders meeting ASTM C 1866.

Recently ASTM recognized ground Glass Pozzolans in a new standard ASTM C 1866. The standard identifies two types of glass. Type GS is soda-lime glass (ACAS Grades) used to make beverage containers and plate glass windows. Type GE is E Glass (VCAS Grades) used to make fiberglass reinforcements. Both types of glass are very pure and quite reactive at the required particle size of 95% passing 325 mesh (about 4000 Blaine) The major difference between the two types is that type GE effectively mitigates alkali–silica reaction (ASR) for even the most reactive aggregates like the New Mexico and Spratt aggregates, whereas Type GS (ACAS Grades), while very pozzolanic, will not mitigate ASR due to a 12% alkali content.

VCAS™ Pozzolans (Type GE) are made from Vitrified Calcium Aluminio-Silicate material having low alkali content, consistent chemistry, uniform color and a wholly amorphous (glassy) state caused by rapid water quenching of the extruded molten material. After primary sizing and drying, the feed stock is finely ground and processed through high efficiency classifiers to produce a fine White powder with quality assured physical properties. The consistent chemical composition and tightly controlled particle size distribution offers excellent repeatability of properties in concrete applications. Currently, the VCAS™ patented technology produces pozzolans in three grades: VCAS™ Ultra 200, VCAS™ 140 and VCAS™ 160.

VCAS 160™ and VCAS™ 140 are commonly used in systems with low w/c ratio and steam cured or warm weather curing conditions where the lower reactivity associated with a 4000 Blaine product is sufficient for the application. VCAS™ 200 has a much finer particle size and has the reactivities normally associated with silica fume and metakaolin with the advantage of being White in color. All VCAS™ grades exhibit approximately 10% lower water demand than silica fume or metakaolin and can be used at cement replacement levels of up to 40%.

VCAS™ Pozzolans are “green” construction materials made from industrial by-products that help contribute to the sustainability of cement and concrete. VCAS™ Pozzolans use in concrete replaces an equal amount of cement resulting in energy conservation and CO2 emission reductions from cement manufacturing. For every ton of cement manufactured, about 3.5 million BTUs energy are consumed and one ton of carbon dioxide is released.

Type GS has two subcategories, Plate glass (ACAS Grades) and bottle glass. The ACAS Plate is very white and pure and contains no organic or label remnants. Bottle glass is consumer recycled, tan in color, and must be carefully cleaned to remove organics and label remnants.

Potters Industries has three types of glass pozzolans; Type GE Glass VCAS Grades, Type GS Plate glass ACAS Grades and HR 50 Fumed Nanosilica Glass, an extremely reactive, very white pozzolan to replace silica fume.

Product Uses

Pozzolan for cement, mortar, concrete, stucco, faux stone, and related products.

Product Overview

SODIUM SILICATE

Multi-Functional Additive in Products and Processes

- Efficient setting agent in cementitious grouts and construction products.

- Critical component in mining chemical systems.

- Effective dispersant in mineral flotation.

- Prime ingredient in pulp bleaching and deinking processes.

- Environmentally friendly binders for multiple applications including beneficial fines.

- Zero VOC adhesives for various applications.

- Increased production output in coated boards.

- Builder and alkali source in detergents and cleaners.

- Reliable coagulant in the treatment of industrial and municipal water.

- Key raw material in the manufacture of other silicate derivatives.

POTASSIUM SILICATE

Versatile, Enhanced Performance Additive

- Primary additive for concrete densification, hardening & sealing.

- Highest plant available silicon source for crop nutrition.

- Superior functional coatings for stain blocking, anti-corrosion and exterior durability.

- Preferred binder for welding rods to produce smoother and quieter burning arc.

- Binders for fire and acid resistant mortar and cement.

- Reduce salinity with potassium silicate-based drilling fluids.

LITHIUM SILICATE

Specialty, High Performance Additive

- Deliver the highest gloss in concrete polishing.

- Inhibit the detrimental alkali-silica reaction in concrete structures.

- Binders for high performance flame retardant coatings, refractory and ceramics.

ZEOLITE

Eco-Friendly Additive for Industrial Applications

- Lead free alternative in PVC stabilizer formulations.

- Builder in phosphate free detergents.

TAILORED CHEMICAL SOLUTIONS

- Customise blending and packaging services

- Formulate new products and solutions to suit specific customer and market requirements.